First. Process flow Wire and cable manufacturing is com […]

First. Process flow

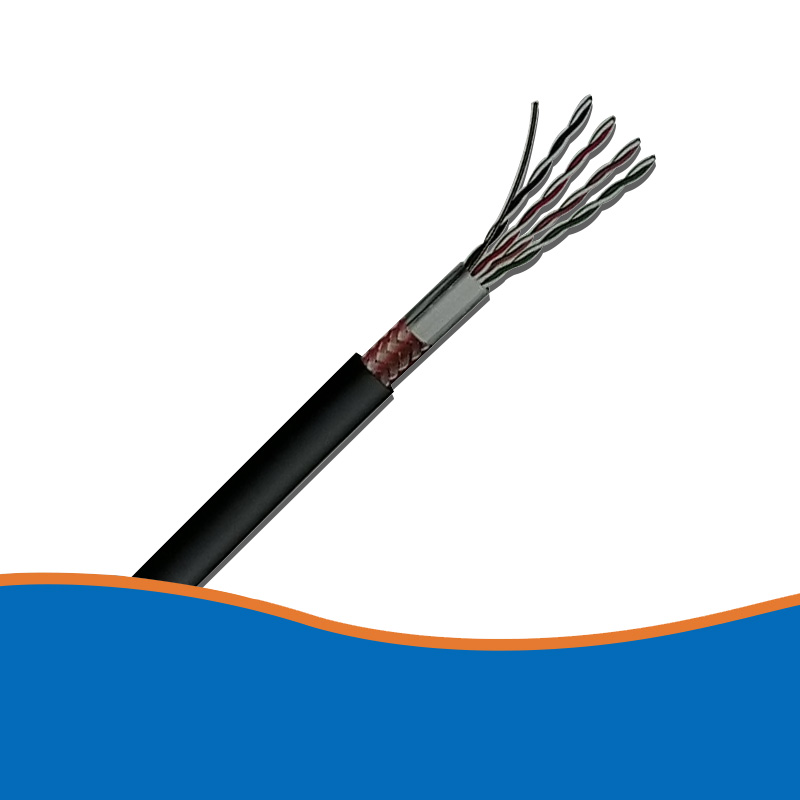

Wire and cable manufacturing is completely different from most electromechanical products. Electromechanical products are usually assembled by assembling parts into parts, and then assembling multiple parts into a single product. The products are measured in units or pieces. Wire and cable are based on length as the basic unit of measurement. All wire and cable are processed from conductors, and insulation, shielding, cable formation, protective layer, etc. are added layer by layer on the periphery of the conductor to make wire and cable products. The more complex the product structure, the more layers there are.

Second. Process characteristics

1. The large-length continuous superposition combined production method has a global and controlled influence on the production of wires and cables. This involves and affects:

(1) Production process and equipment layout

The various equipment in the production workshop must be reasonably discharged according to the technological process required by the product, so that the semi-finished products at various stages can be sequentially transferred. The equipment configuration should consider the different production efficiency and balance the production capacity. Some equipment may have to be equipped with two or more units in order to balance the production capacity of the production line. Therefore, the reasonable combination of equipment and the layout of the production site must be balanced and comprehensively considered according to the product and production volume.

(2) Production organization management

Production organization management must be scientific and reasonable, thorough and accurate, strict and meticulous, the operator must carry out meticulously according to the process requirements, any problem in any link will affect the smooth flow of the process and affect the quality and delivery of the product. Especially for multi-core cables, if the length of a pair or the basic unit is short, or the quality is in question, the entire cable will not be long enough, resulting in scrapping. Conversely, if a unit is too long, it must be sawn to cause waste.

(3) Quality management

The production method of continuous stacking of large lengths makes any problems in the production process instantaneous and will affect the quality of the entire cable. The more quality defects occur in the inner layer, and if the production is not stopped in time, the greater the loss. Because the production of wire and cable is different from assembled products, it can be disassembled and reassembled and replaced; the quality of any part of the wire or cable or the process is almost irreparable and irreparable for this cable. Afterwards, the treatment is very negative, either sawing is shortened or downgraded, or the entire cable is scrapped. It cannot be disassembled and reassembled.

Wire and cable quality management must run through the entire production process. The quality management inspection department should conduct a round-trip inspection of the entire production process, the operator's self-inspection, and the mutual inspection of the upper and lower processes. This is an important guarantee and means to ensure product quality and improve the economic efficiency of the enterprise.

2. There are many production process categories and large material flow

Wire and cable manufacturing involves a wide range of processes, from smelting and pressure processing of non-ferrous metals, to chemical technologies such as plastics, rubber, paint, etc.; textile technologies such as fiber wrapping and weaving, to metal wrapping and metal strips Vertical ladle, welded metal forming process, etc.

The various materials used in the manufacture of wire and cable are not only of many types, varieties and specifications, but also of large quantity. Therefore, the amount of various materials, spare volume, batch cycle and batch must be approved. At the same time, the decomposition and treatment of waste products, recycling, reuse and waste disposal, as an important part of management, do a good job of material quota management and pay attention to conservation work.

In the production of wire and cable, from the entry and exit of raw materials and various auxiliary materials, the flow of semi-finished products in each process is transferred to the storage and delivery of the product. The material flow is large, and it must be reasonably arranged and dynamically managed.

3. Special equipment

Wire and cable manufacturing uses special production equipment with the characteristics of this industry process to meet the structure and performance requirements of cable products, to meet the requirements of large-length continuous and high-speed production, thus forming a series of special equipment for cable manufacturing. Such as extruder series, wire drawing machine series, stranding machine series, wrapping machine series, etc.

The manufacturing process of wire and cable is closely related to the development of special equipment and promotes each other. New technology requirements promote the production and development of new special equipment; in turn, the development of new special equipment promotes the promotion and application of new technology. Special equipment such as wire drawing, annealing, extruding series lines; physical foaming production lines, etc. have promoted the development and improvement of wire and cable manufacturing processes, and improved the product quality and production efficiency of cables.